Brief Introduction of Zero Defect Waterproof Service System

Project Insurance Mechanism of Zero Defect Waterproof Service System

Design Idea of Zero Defect Waterproof Service System

Comprehensive Introduction

Zero Defect Waterproof System

Zero Defect Waterproof System was officially launched in 2014, which is the 1st comprehensive waterproof service system in China Building Waterproofing Industry, covering design, material, construction, supervision, guarantee and other aspects involved.

The system structure mainly adopts Bondsure® Self-adhesive Waterproof Membranes + NRB Non-curing Rubber Bitumen Waterproof Coating togehter, to form a Skin Type waterproof system. Zero Defect System provides the first waterproof engineering quality assurance insurance in the industry.

It promises to be responsible for the result of "no leakage". Until June 30th, 2021, it has been successfully applied in over 21,260,000㎡ of waterproof projects, equivalent of 2,978 international standard football fields, and no compensation asked for.

Till now, Joaboa Tech is still the ONLY 1 in Chinese mainland who can provide project insurance for the waterproof projects.

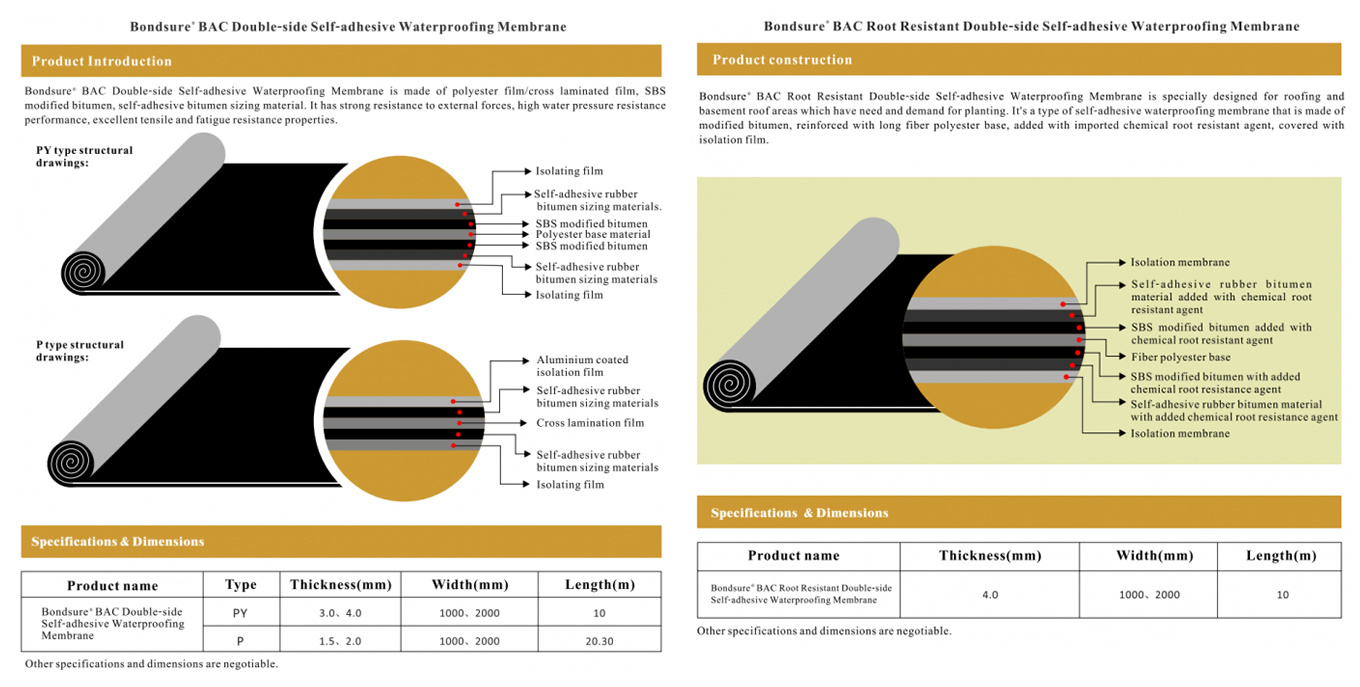

Introduction of Bondsure Self-adhesive Waterproofing Membrane Series

With excellent characteristics of tensile strength and fatigue resistance ability, Joaboa Tech Bondsure® Self-adhesive Bituminous Waterproofing Series have been regarded as the representative of self-adhesive membranes in China for more than 20 years.

Bondsure® Membrane Series consist of Single-sided Self-adhesive Membranes(like PET, CLF, S-CLF NS Type), Double-sided Self-adhesive Membranes(like BAC, BAC-P, S-CLF ND Type), Pre-applied Membrane (S-CLF YC Type, MAC), Torch-applied Membranes(SBS, APP), Synthetic Membranes (PVC, TPO, Self-adhesive TPO) and Root-resistant Membranes(Root-resistant BAC/PVC/SBS/TPO), etc.

For Zero Defect System, Bondsure® Single-sided Type, Double-sided Self-adhesive Type, BAC Root-resistant Self-adhesive Type will be chosen.

Introduction of NRB Non-curing Rubber Bitumen Waterproofing Coating

NRB Rubber Bitumen Waterproofing Coating is a kind of sticky and pasty waterproofing coating inapplication condition, which is made up of rubber, bitumen and other auxiliaries.

Before application, it will be heated to flowing type and form a perfect waterproofing layer with strong adhesion, creep property and self-healing performance.

It can be used as a separate waterproofing layer, but can also be applied together with waterproofing membranes to form into composite system.

Reference dosage: 2.5kg/2mm/m2

Packages: 20kg /pail

System Features

01

Strong resistance to external forces, excellent tensile and fatigue resistance performance.

02

After application, there won't be fluid-channeling between waterproofing membrane layer and waterproofing coating layer. Even if there are any small damages, the water will be strictly limited in a small scale, it will not flow here and there.

03

As NRB Non Curable Rubber Bitumen Waterproofing Coating will be heated into flow type as bonding layer before applied with waterproofing membranes, it will be possible and rather convenient for the construction in cold winter.

04

Waterproofing Membranes are designed and produced as double-sided self-adhesive type, which will greatly enhance the reliability and safety of the waterproofing system, as well as convenient for the application.

Scope of Application

Zero Defect Waterproof System is applicable to waterproof and anti-seepage projects in basement, roof, and other parts of industrial and civil buildings.

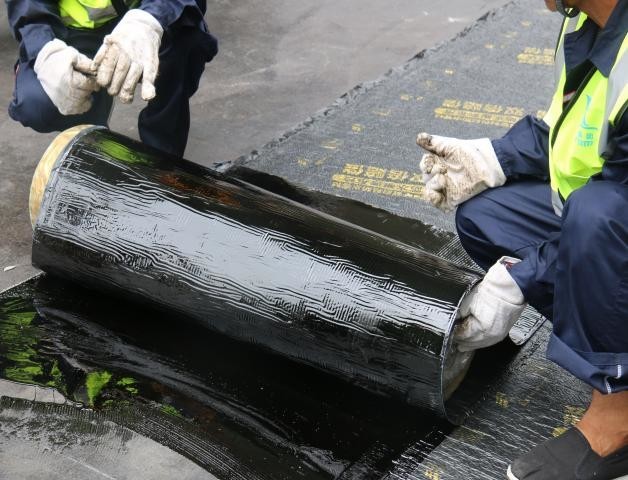

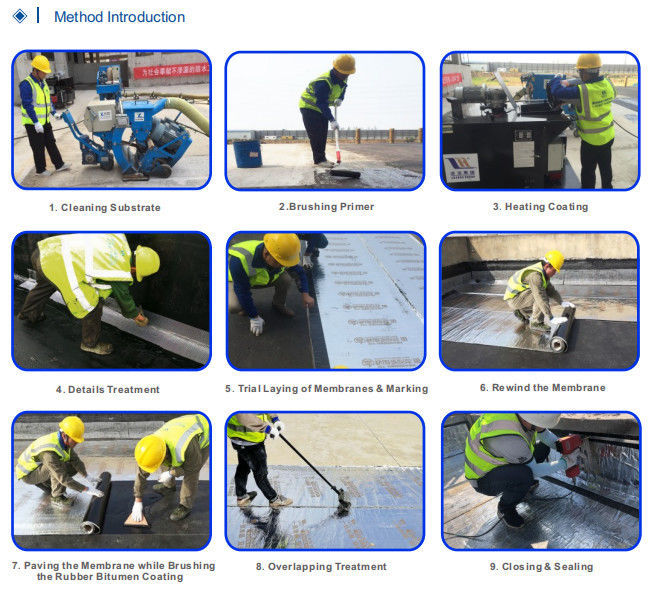

Construction Methods

Zero Defect Waterproof System can use construction method as below:

Hot Application.

Introduction of Hot Application

HOT APPLICATION is composite of rubber asphalt waterproof coating and self-adhesive membrane which is closely bonded with the base layer to form a "skin-type" waterproof system. It is an organic whole with complementary advantages, which can adapt to the deformation and self-healing performance of the base, effectively prevent water channeling and reduce leakage hazards.

Substrate Requirements

1) The firmness and strength of the base layer should meet the design requirements.

2) The surface of the base layer should be clean and smooth, and there should be no quality defects such as powdering, sanding, peeling, voids and pits.

3) Remove sundries, greasy dirt, sand, etc. on the surface of the base layer, and the cleaning work must be carried out at any time during the construction.

4) If there is clear water on the base layer, it needs to be cleaned before construction. If the base surface is relatively damp, it needs to be dried with a blower.

Storage and Transport

1. Different types or specifications of products should be separated, not mixed.

2. Keep it dry and ventilated, protected from the sun or rain.

3. Storage temperature should not be higher than 45 ℃. Pile up the membranes flatwise whose stockpile height should not exceed five layers.

4. Prevent tilt or side pressure during transportation, and cover with felt if necessary.

5. Storage time is at least one year from manufacture date if the product is under normal storage condition.

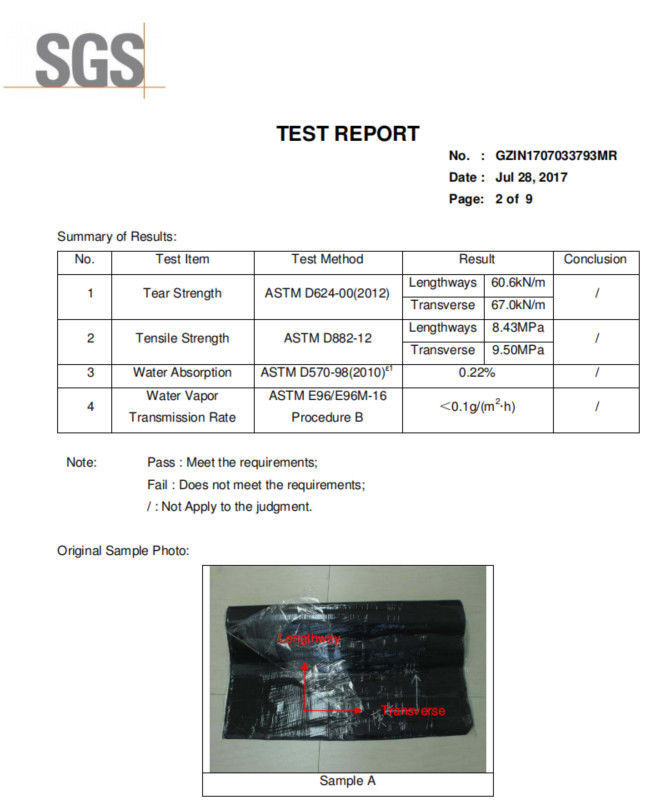

International & Domestic Certificate

ASTM Testing Report of Bondsure® S-CLF Super Tensile Strength Self Adhesive Waterproofing Membrane (NS Type)

S-CLF has been approved by the Evaluation Committee of Science and Technology Development Promotion Center of Ministry of Housing and Urban-Rural Construction.

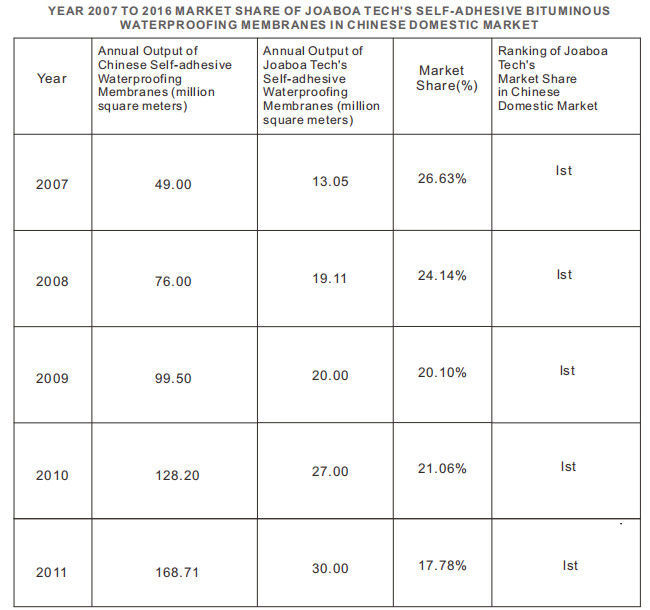

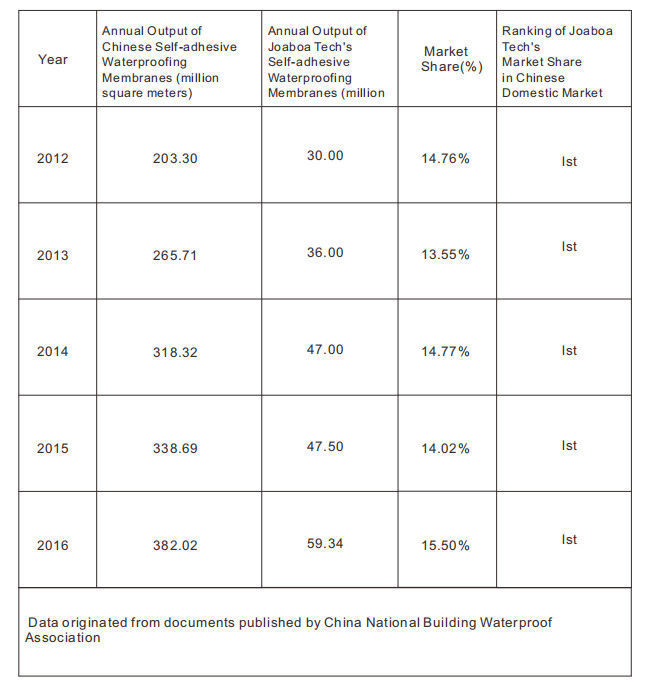

Market Share

Joaboa Tech, Inventor and Representative Brand of Chinese Self-adhesive Waterproof Membrane, whose market share has ranked as Top 1 in Chinese domestic market for over 10 years, widely used in Viet Nam, Cambodia, India, etc. as well.

Document Download

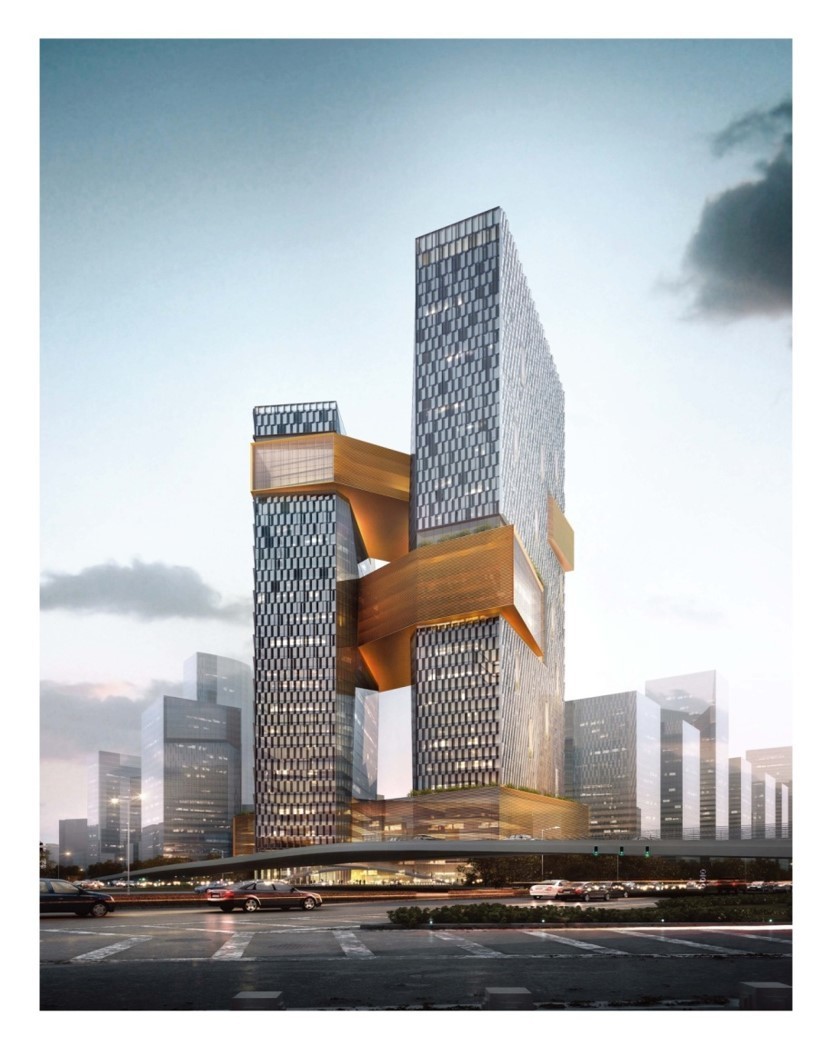

Landmark Projects