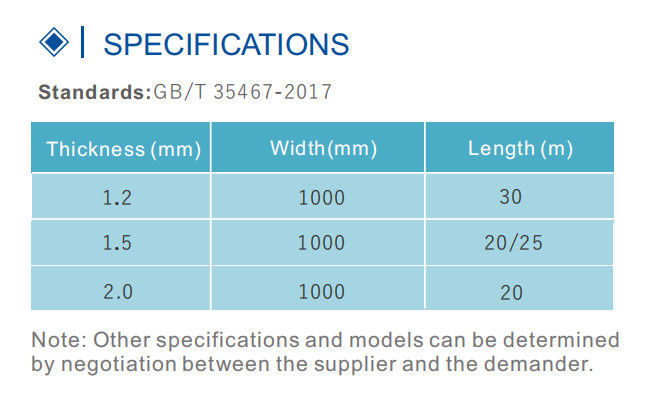

Bondsure® PET Bituminous Waterproofing Membrane Aluminum Foil Covered Self Adhesive

Place of Origin:

CHINA

Brand Name:

JOABOA TECH

Certification:

CE, BBA, SGS, ISO, SIRIM

Model Number:

PET

Minimum Order Quantity:

1,000㎡

Packaging Details:

With or without pallets; For 1.5mm thickness, 11,500 ㎡ can be loaded into 1x20GP if without pallets.

Supply Ability:

10,000,000㎡ per Month

Application Methods:

Wet Application, Hot Application, Dry Application

Tear-resistance:

Waterproof:

Type:

No content displayed at the moment

- Product Details

-

- Commodity name: Bondsure® PET Bituminous Waterproofing Membrane Aluminum Foil Covered Self Adhesive

- Place of Origin: CHINA

- Brand Name: JOABOA TECH

- Certification: CE, BBA, SGS, ISO, SIRIM

- Model Number: PET

- Minimum Order Quantity: 1,000㎡

- Packaging Details: With or without pallets; For 1.5mm thickness, 11,500 ㎡ can be loaded into 1x20GP if without pallets.

- Supply Ability: 10,000,000㎡ per Month

- Application Methods: Wet Application, Hot Application, Dry Application

Place of Origin

CHINA Brand Name JOABOA TECH Certification

CE, BBA, SGS, ISO, SIRIM Model Number PET Application Methods:

Wet Application, Hot Application, Dry Application Minimum Order Quantity 1,000㎡ Packaging Details With or without pallets; For 1.5mm thickness, 11,500 ㎡

can be loaded into 1x20GP if without pallets.

Supply Ability 10,000,000㎡ per Month Highlight: PET Bituminous Waterproofing Membrane, Aluminum Foil Covered Bituminous Waterproofing Membrane, Adhesive Backed Waterproof Membrane

Product Description

Bondsure™ Membrane Series

Bondsure® PET Aluminum Foil Covered Self-adhesive Bituminous Waterproofing Membrane is made of polyester film(aluminum-plastic composite film), self-adhesive rubber asphalt adhesive material and isolation film.

The polymer (chain segment) in the rolling material adhesive and cement hydrate (silicate network) form (interface) interpenetrating network (IPN) structure. The cement can flow and penetrate before the initial setting, then solidification strength increases day by day, the bonding strength is enhanced.

The fluidity of cement slurry realizes the micro full adhesion between the membrane and cement slurry, so that PET membrane becomes the "skin" of structural concrete, even if the damage point appears, there will be no "water channel" phenomenon.

※ Material Features

1. Cost-Effective

Manufactured by patented production technology, PET adhesive backed waterproof membrane can be bonded with unsolidified cement, to completely eliminate water-channeling.

2. Unique Wet-application Technology

PET sbs peel and stick roofing can be applied on wet or uneven substrate surface. No need of primer, not affected by the weather. Especially during rainy season, the advantage is more prominent when compared with hot-applied membrane.

3. Reliable Bonding of Overlapping Edges

As PET self adhesive bitumen roofing is self-adhesive type, it's very easy to do the treatment of overlapping areas.

4. Strong Bonding Strength

PET sticky roof membrane can be bonded tightly to the substrate, if there is local failure on the membrane, water would be confined in a limited area without fluid-channeling, which makes it much easier to repair.

5. Safe & Environmental-friendly

During construction, there is no solvent or fuel involved. Avoiding pollution, fire risks and saving resources as well.

※ Scope of Application

PET self adhesive bitumen roll is applicable to waterproof and anti- seepage projects in basement, roof and other parts of industrial and civil buildings.

※ Peel and Stick Modified Bitumen Installation

PET Aluminum Foil Covered Self-adhesive Bituminous Waterproofing Membrane can use construction methods as below: Wet Application, Hot Application, Dry Application.

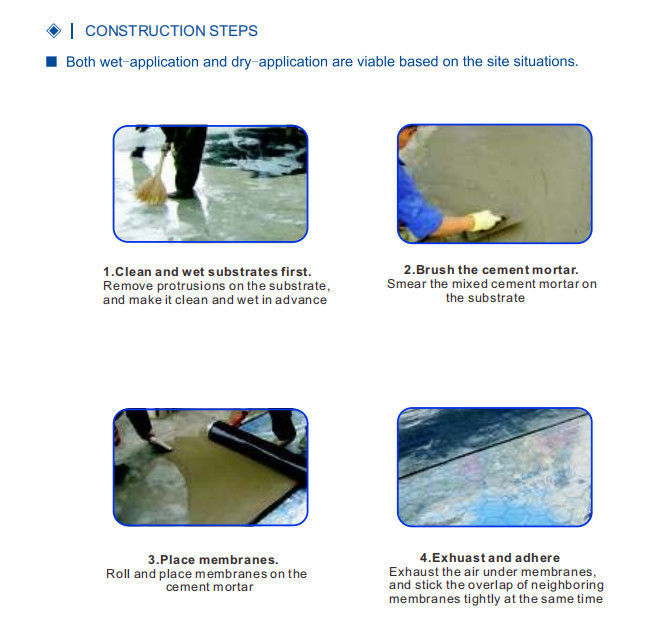

1. Wet Application

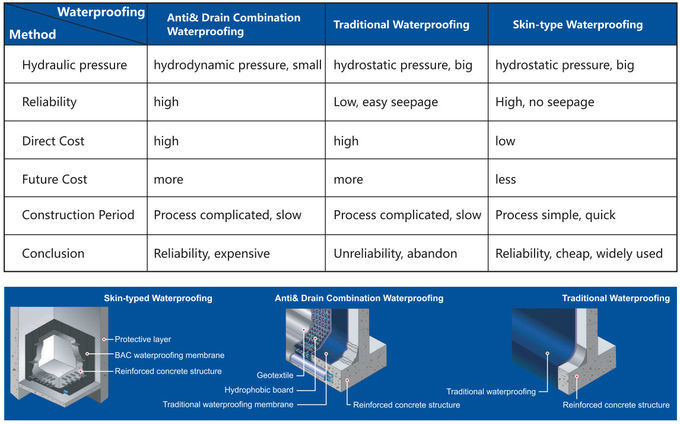

Wet Application is to use cement paste or cement mortar as bonding material to bond the membrane with the base course. This invention is a huge renovation for the waterproof industry. It not only reduces the requirements for the base course during the construction of waterproof membrane, but also greatly improves the bonding effect.

Description of cement mortar used in wet application:

The water-cement ratio is between 0.35 and 0.4, the thickness of the coating on the base is controlled in 3-5mm. Note that the base surface needs to be wet with water first (wet, no visible water), then scratched cement mortar. During the paving of membrane, we should pay attention to exhaust the air, so that the membrane and cement mortar can be completely bonded with each other.

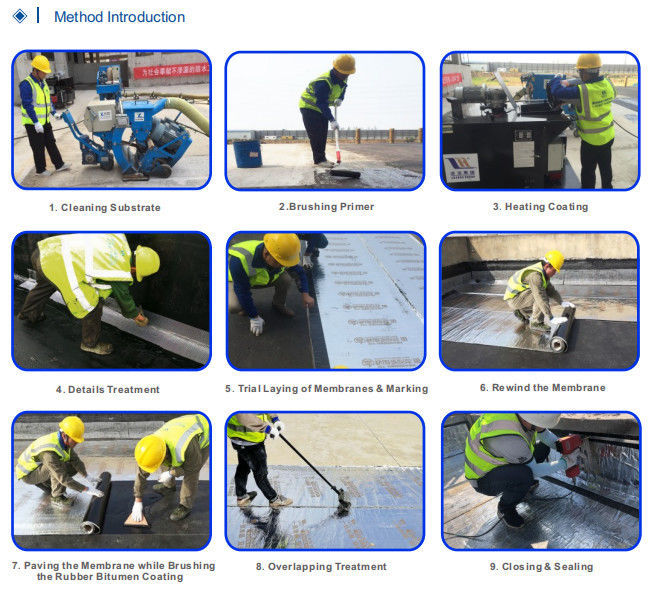

2. Hot Application

HOT APPLICATION is composite of rubber asphalt waterproof coating and self-adhesive membrane which is closely bonded with the base layer to form a "skin-type" waterproof system. It is an organic whole with complementary advantages, which can adapt to the deformation and self-healing performance of the base, effectively prevent water channeling and reduce leakage hazards.

Substrate Requirements

1) The firmness and strength of the base layer should meet the design requirements.

2) The surface of the base layer should be clean and smooth, and there should be no quality defects such as powdering, sanding, peeling, voids and pits.

3) Remove sundries, greasy dirt, sand, etc. on the surface of the base layer, and the cleaning work must be carried out at any time during the construction.

4) If there is clear water on the base layer, it needs to be cleaned before construction. If the base surface is relatively damp, it needs to be dried with a blower.

3. Dry Application

If the substrate condition can meet with designed and standard requirements, flat, even, dry and without dirties, after covering the base surface with primer, the membranes can be paved directly. Al l pipe fitting should be pre-covered as designed and standard requirements, and to be seal treated. The internal and external corners of substrate wipe to circular. The min radius of internal corners is 50mm and the max radius of external is 20mm.

Make sure the moisture content less than 9% (Dry test: pave 1 ㎡ membrane smoothly on the screed-coat, then check the membrane paved side whether has watermark or not after 3~4 hours, if not, it can be constructed).

※ Storage and Transport

1. Different types or specifications of products should be separated, not mixed.

2. Keep self adhesive roofing underlayment dry and ventilated, protected from the sun or rain.

3. Storage temperature should not be higher than 45 ℃. Pile up the membranes flatwise whose stockpile height should not exceed five layers.

4. Prevent tilt or side pressure during transportation, and cover with felt if necessary.

5. Storage time is at least one year from manufacture date if the product is under normal storage condition.

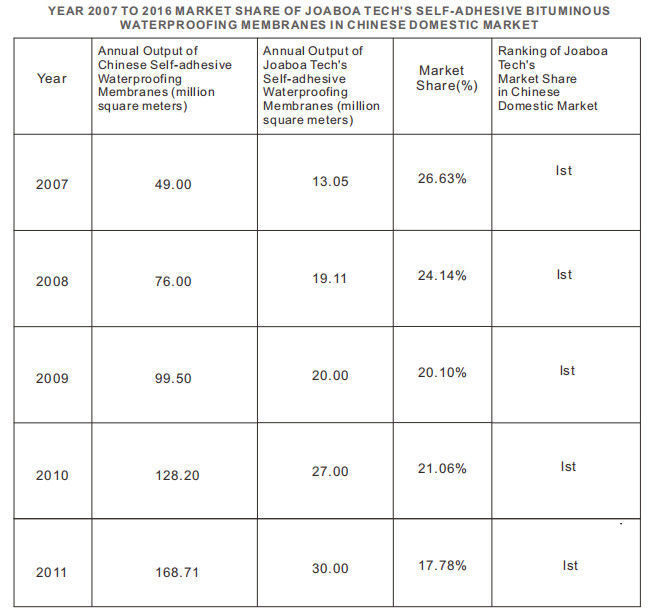

※ Market Share

Joaboa Tech, Inventor and Representative Brand of Chinese Self-adhesive Waterproof Membrane, self adhesive waterproofing, waterproof membrane adhesive, adhesive waterproof sheet, self adhesive bituminous membranes, bituminous sheet waterproofing membrane, self adhesive waterproof flashing tape, adhesive waterproof membrane, whose market share has ranked as Top 1 in Chinese domestic market for over 10 years, widely used in Viet Nam, Cambodia, India, etc. as well.

Leave a Message

We will call you back soon!